To mark Global Recycling Day on 18 March, GRF has urged policy makers to adopt laws and technologies to make the sector greener and more circular globally.

Iron and steel-making is the world’s largest coal consumer, the largest emitter of CO2 and second largest energy consumer among heavy industries. It accounts for 7-9% of global carbon dioxide emissions, more than the emissions from all road freight.

Global demand for steel has trebled since 1970 and is set to increase by more than a third between now and 2050. Much of this demand will come from the wind turbines, solar panels, hydroelectric dams and electric cars, buses, and trains that the world will need to reach net zero.

GRF founding President, Ranjit Baxi, said: “This represents a significant challenge. But it also provides a huge opportunity to re-set the world’s iron and steel value chains on a more sustainable path.”

Mr Baxi stressed: “Our call resonates with the ambition of COP28 to accelerate energy transition when it unveiled the Global Decarbonization Accelerator (GDA), a series of landmark initiatives designed to speed up the energy transition and drastically reduce global emissions. As COP28 President HE Dr Sultan Al Jaber said, the GDA adds up to more countries and more companies from more sectors than ever before, in the drive towards the goal of 1.5C.”

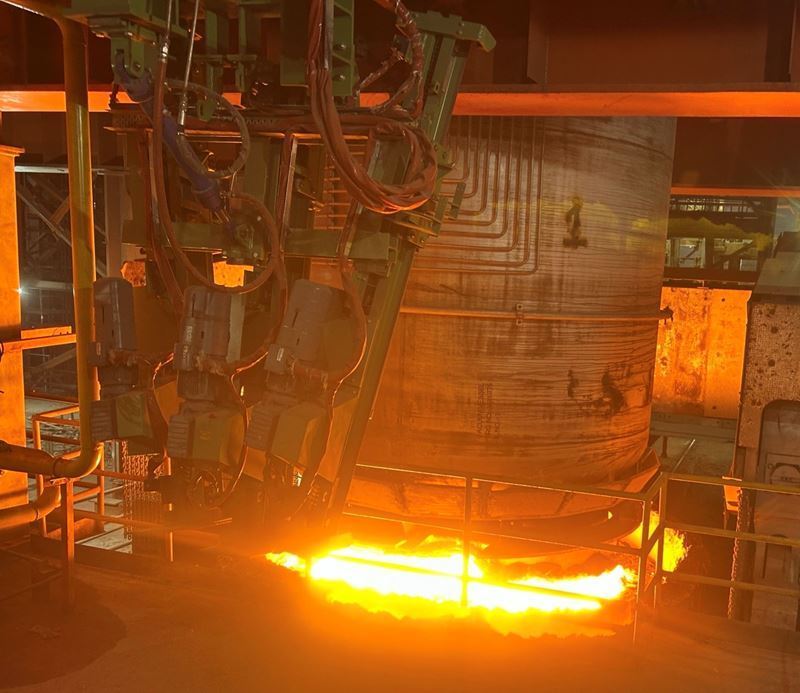

President of the Bureau of International Recycling, BIR, Susie Burrage, added: “To decarbonise iron and steel, we’ll need green hydrogen, carbon capture and storage (CCS) and electric arc furnace (EAF) technologies. We’ll need to use steel less wastefully, to recycle a lot more and to make renewable energy cheaper for steel makers, users and re-users. These things won’t just happen, they will require a combination of innovation and the right laws, regulations, and incentives.

Notes for editors:

Steel facts and figures

• In 2022, according to Statistia, 52% of the world’s steel was used for building and infrastructure, 16% for mechanical equipment and 12% for automotive products.

• Every tonne of scrap used for steel production avoids 1.5 tonnes of CO2 emissions and the consumption of 1.4 tonnes of iron ore, according to Worldsteel

• According to Global Energy Monitor, in 2023, 43% of planned steelmaking capacity was based on EAF technology. The International Energy Agency Net Zero by 2050 scenario calls for 53% of steelmaking capacity to use EAF by 2050.

• Steel production is the most electrified in the Middle East, where 95% of steel capacity is from EAFs. In the US. it’s 70%. In India, the world’s second-largest steel producer, over 54% of the country’s steel is produced from EAFs. In the EU, it’s 44%.

• JFE Steel in Japan is set to open one of the world’s largest EAFs by 2027. It is expected to produce 2 million metric tons of steel annually and cut CO2 emissions by 2.6 million tonnes per year It will import processed iron ore, ‘reduced iron’, from the United Arab Emirates, created using natural gas and CCS.

• The EU’s End-of-Life Vehicles Directive species a minimum recycled metal content in new vehicles. Its carbon border adjustment Mechanism (CBAM) could be extended to reduce the embodied carbon of imported vehicles.

• In the UK, Zero Waste Scotland’s proposes using scrap steel from decommissioning oil and gas wells to supply wind turbine manufacturers. The UK’s high-speed rail line, HS2, has used almost 20,000 tonnes of recycled steel in the past two years.

Source: Bureau of International Recycling, BIR

Comments

No comment yet.