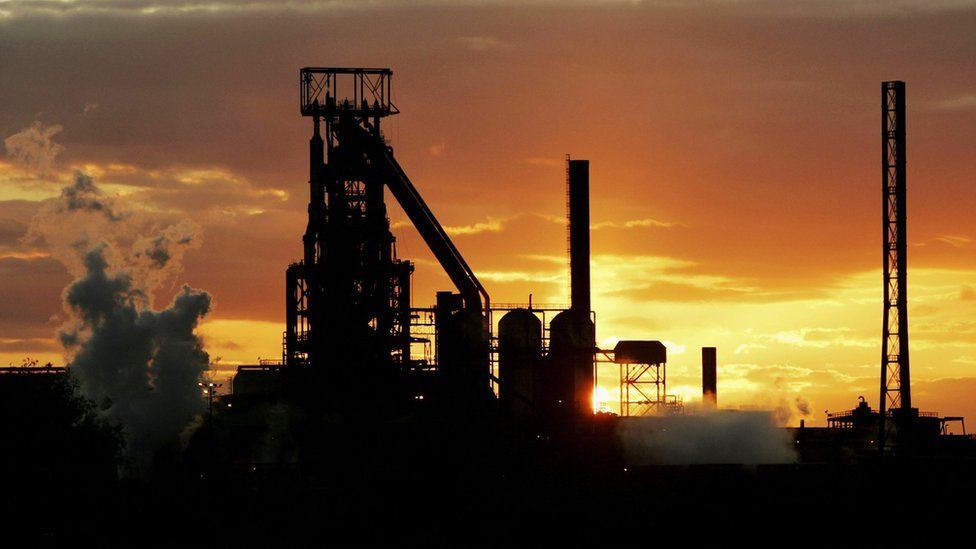

The EAF will replace the Port Talbot plant's old blast furnaces and will utilize scrap from the UK. The 2-2.5 million tons of scrap to be processed annually is reportedly expected to decrease the country's dependence on imported iron ore and contribute to a more sustainable supply chain. This development is seen as a major advance not only in economic terms but also in terms of environmental sustainability.

Scheduled to be commissioned by the end of 2027, the new EAF aims to reduce carbon emissions from Tata Steel's steel production by 90%, avoiding 5 million tons of CO₂ emissions annually. This will not only improve the company's environmental performance, but also make a significant contribution to the UK's climate targets.

As part of the project, the ladle furnaces will also be supplied by Tenova and this equipment will be used to produce more complex steel grades. In addition, various equipment investments will be made to extend the life of the Port Talbot plant's hot strip rolling mill and casting machines. These investments include a new pickling line and cranes, while additional orders are planned for construction management and engineering services.

Tata Steel has completed the planning application process in public consultation, recognizing the importance of community engagement in this transformation process. The company plans to submit its application to the authorities in November 2024, with large-scale construction expected to begin in July 2025.

This strategic move is strengthened by the support of the UK government. Tata Steel will invest a total of £1.25 billion, with funding of up to £500 million from the government. These investments will modernize production at the Port Talbot plant and are seen as a major milestone towards achieving environmental targets in the steel industry.

Comments

No comment yet.