In a groundbreaking analysis conducted in 2023, researchers unveiled a stark contrast in carbon emissions between traditional blast furnace techniques and more modern electric arc furnaces (EAF). These findings have significant implications for the steel industry and the environment.

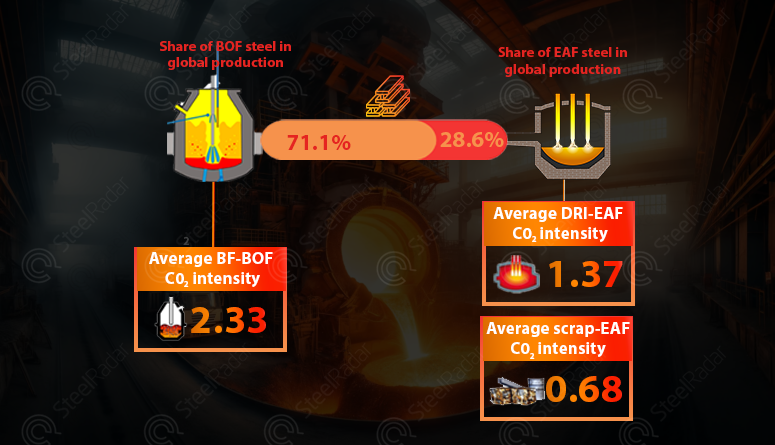

Blast furnaces accounted for a whopping 71.1% of global steel production in 2023. These iconic structures have long been the workhorses of the industry. However, there’s a trade-off. For every ton of steel produced via blast furnaces, approximately 2.33 tons of carbon dioxide (CO2) are emitted. The high-intensity process relies on coke (derived from coal) to extract iron from ore, releasing substantial greenhouse gases.

EAF, representing 28.6% of global production, offer an alternative. They use electricity to melt scrap steel, bypassing the need for coke.

The average CO2 intensity for EAF using direct reduced iron (DRI) methods is 1.37 tons per ton of steel. But the true environment-friendly is the full scrap charge approach, which slashes emissions to a mere 0.68 tons per ton of steel. EAFs are nimble, adaptable, and less resource-intensive. They’re particularly suited for recycling and minimizing environmental impact.

These statistics underscore the need for industry-wide shifts toward greener practices. As climate concerns mount globally, steelmakers must embrace innovation, invest in cleaner technologies, and reduce their carbon footprint.

Remember, the future of steel lies not only in its strength but also in its sustainability. Let’s forge a path toward a cleaner, more resilient world!

Comments

No comment yet.