The collaborative project between the two companies intends to transform slag, a by-product of steel production, into low-carbon binders to replace traditional cement.

Saint-Gobain and SSAB are developing a circular economy process that transforms the by-products of SSAB's steel production into low-carbon binders for Saint-Gobain Weber's dry mortars.

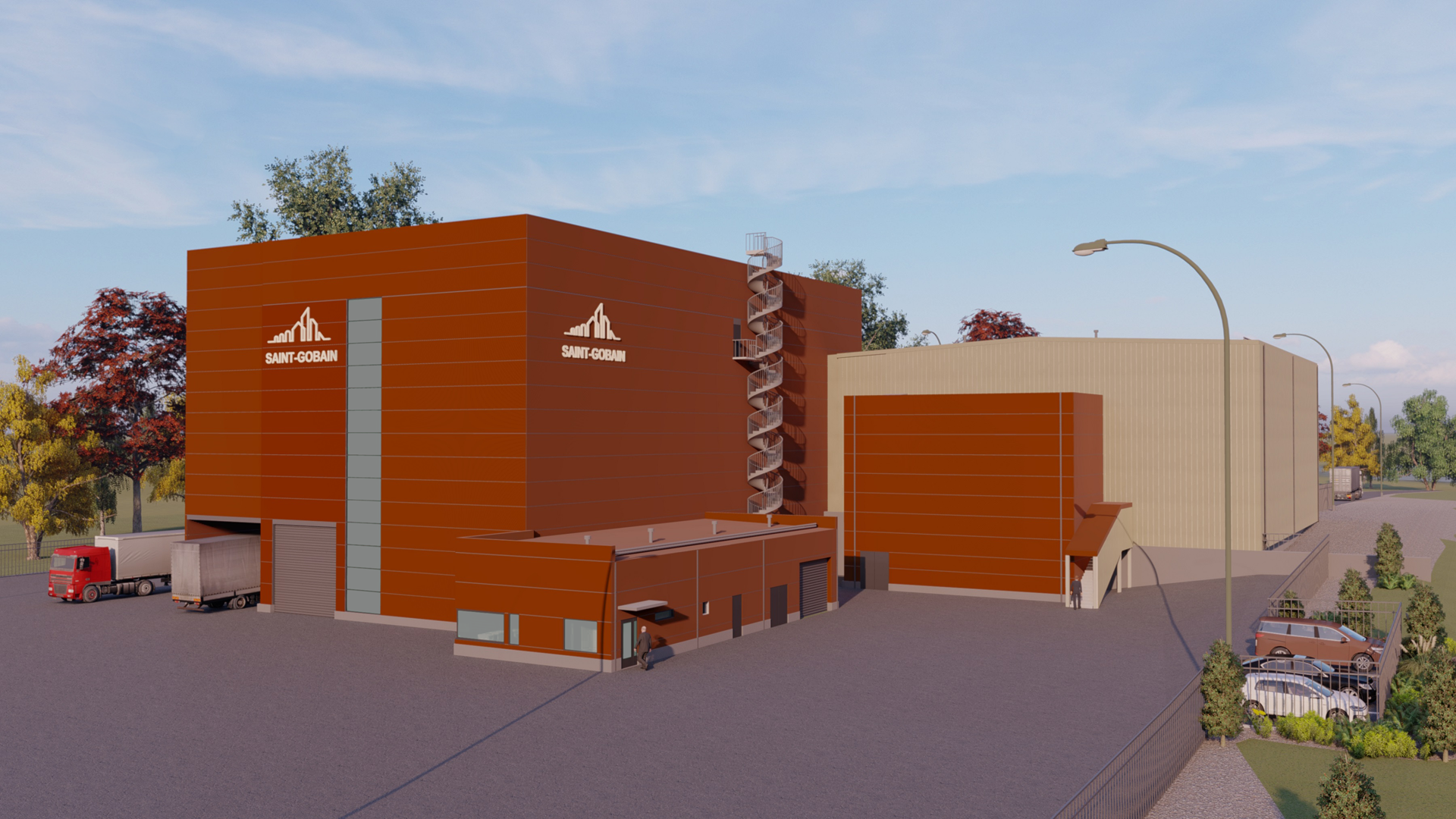

The slag reprocessing plant in Raahe to produce high-value binders that can be used to replace cement with slag from steel production is to be completed in 2025. In terms of carbon footprint, this process means that the binders are up to 90% smaller than conventional cement.

Saint-Gobain and SSAB co-designed this process for five years, and the project, the first of its kind in the world, enables SSAB to recycle 100% of the slag generated in its steelmaking process.

Senior R&D Manager at Saint-Gobain Finland, Gunnar Lauren stated his views on the topic. “When we studied SSAB’s manufacturing process, we noticed that the end step in the processing of special steel has similarities to the production of special cement. We can replace the slag created as a side stream of steel cleaning to replace, for example, the special cement used in Weber dry mortars,” and notes that as part of the project, the plant is to reduce carbon dioxide emissions by 20,000 tons per year.

Marko Mäkikyrö, Director, By-product sales and development at SSAB emphasized the importance of the project in responsible steel production: “This project supports our ambition to be a leader in responsible steelmaking. SSAB has taken a policy decision to transform all its production sites to fossil-free steelmaking. Already at this stage, it is important to ensure that also future by-products are utilized as efficiently as possible and this project is a part of this development.”

Saint-Gobain is investing 12 million euros in the construction of a slag processing plant in the Port of Raahe, Finland. This strategic investment intends to support net zero carbon emissions in Finland by 2025 and globally by 2050. SSAB's investment of €2 million also provides significant support to the project. Furthermore, the project receives 35% funding from Finland's Sustainable Growth Program, which is helping to achieve its sustainability goals.

Comments

No comment yet.