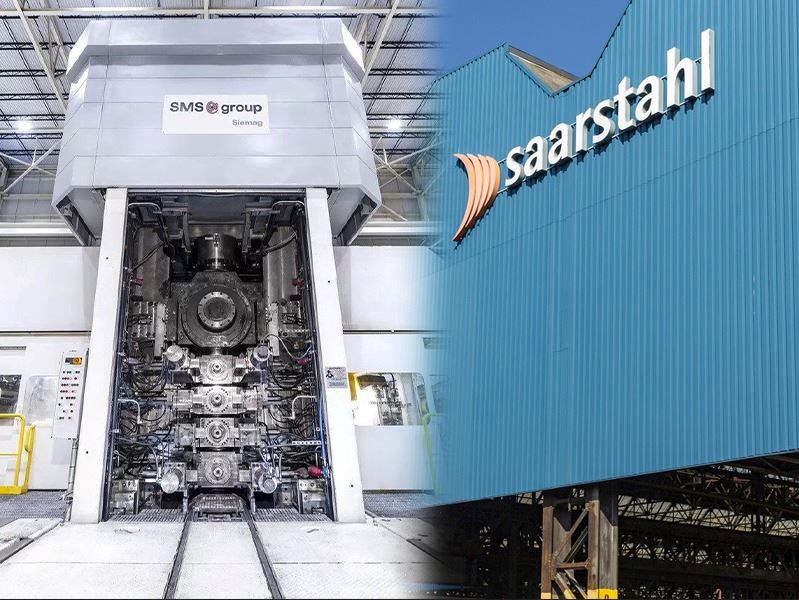

New electric arc furnace (EAF) plays an important role as part of the SHS Power4Steel initiative to support Saarstahl's (SHS) move to eliminate carbon emissions by 2045. The steel produced through this partnership is to serve a variety of sectors, including bearing steel, free-cutting steel, and spring steel. The new EAF is said to be a crucial step towards the company's carbon neutrality.

Jochen Burg, CEO of SMS Group stated: “We are proud to play a key role in Europe's green steel transformation with this major project for Saarstahl and SHS - Stahl-Holding Saar. The project highlights the long-standing partnership between SHS and SMS group. With an installed power of 300 MVA the new EAF is the biggest ever built by SMS group and will set a new milestone in a carbon-neutral future for the European steel industry.”

Saarstahl plans to build the world's most powerful Alternate Current-Electric Arc Furnaces (EAF) system at its plant in Völklingen, Germany.

New 185-tonne EAF with innovative Condoor® slag gate technology developed by SMS Group reduces environmental impact while ensuring safety, efficiency, and energy savings. The furnace, which operates with a flexible material mix of up to 100 percent scrap or 80 percent Cold Direct Reduced Iron (CDRI)/Hot Briquetted Iron (HBI) and 20 percent scrap, plays an important role in achieving Saarstahl's carbon emission reduction targets.

The furnace, expected to contribute green steel production by producing a mixture of natural gas and hydrogen, is seen as an important step towards sustainability in the steel industry.

Comments

No comment yet.