Leading Australian iron ore producers Rio Tinto and BHP, as well as the largest domestic steel producer BlueScope Steel, are launching a joint pilot project to develop a new steelmaking technology based on the use of the electric smelting furnace (ESF).

This technology consists of two stages. In the first stage, iron is reduced using natural gas or hydrogen. In contrast to the traditional process of producing reduced/hot briquetted iron (DRI/HBI), blast furnace pellets or even ore fines can be used in this case.

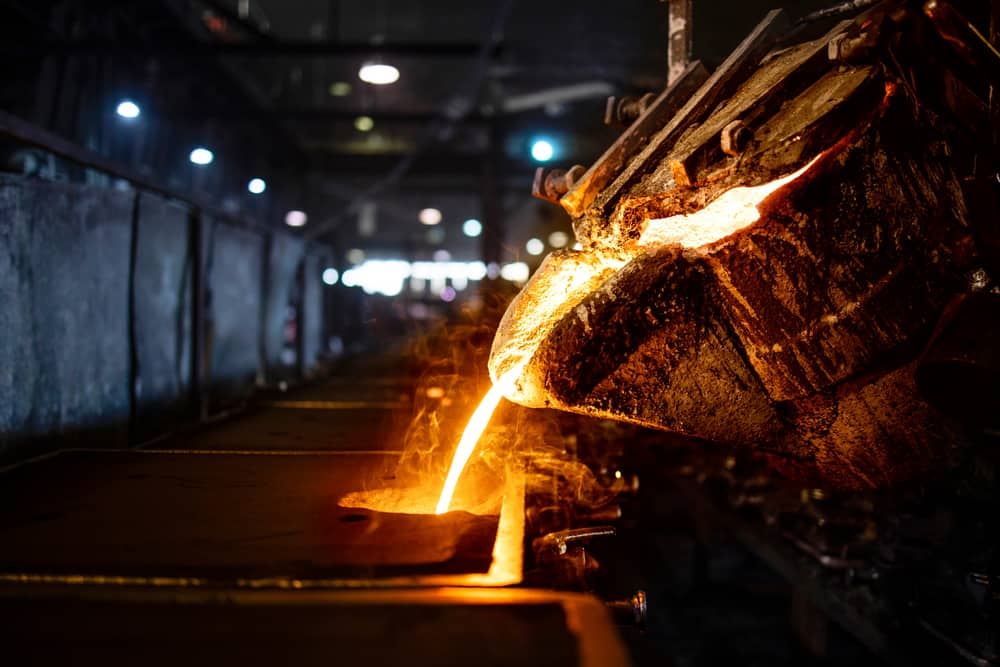

The resulting metalized pellets, which have a lower iron content than DRI/HBI, are sent to the ESF, where they are melted with the removal of impurities in the form of slags. The liquid metal then enters the oxygen converter, where the steel is smelted.

The implementation of this technology will make it possible to replace blast furnaces and abandon the use of coking coal. In the first step, green hydrogen can be used to reduce iron, and ESF can generate energy from renewable sources. Due to this, specific carbon dioxide emissions from steel smelting can be reduced by more than 80%.

The three participants in the project are going to jointly finance the building of a pilot plant that will use iron ore from Western Australia as a feedstock. The project is expected to be completed by 2027.

Comments

No comment yet.