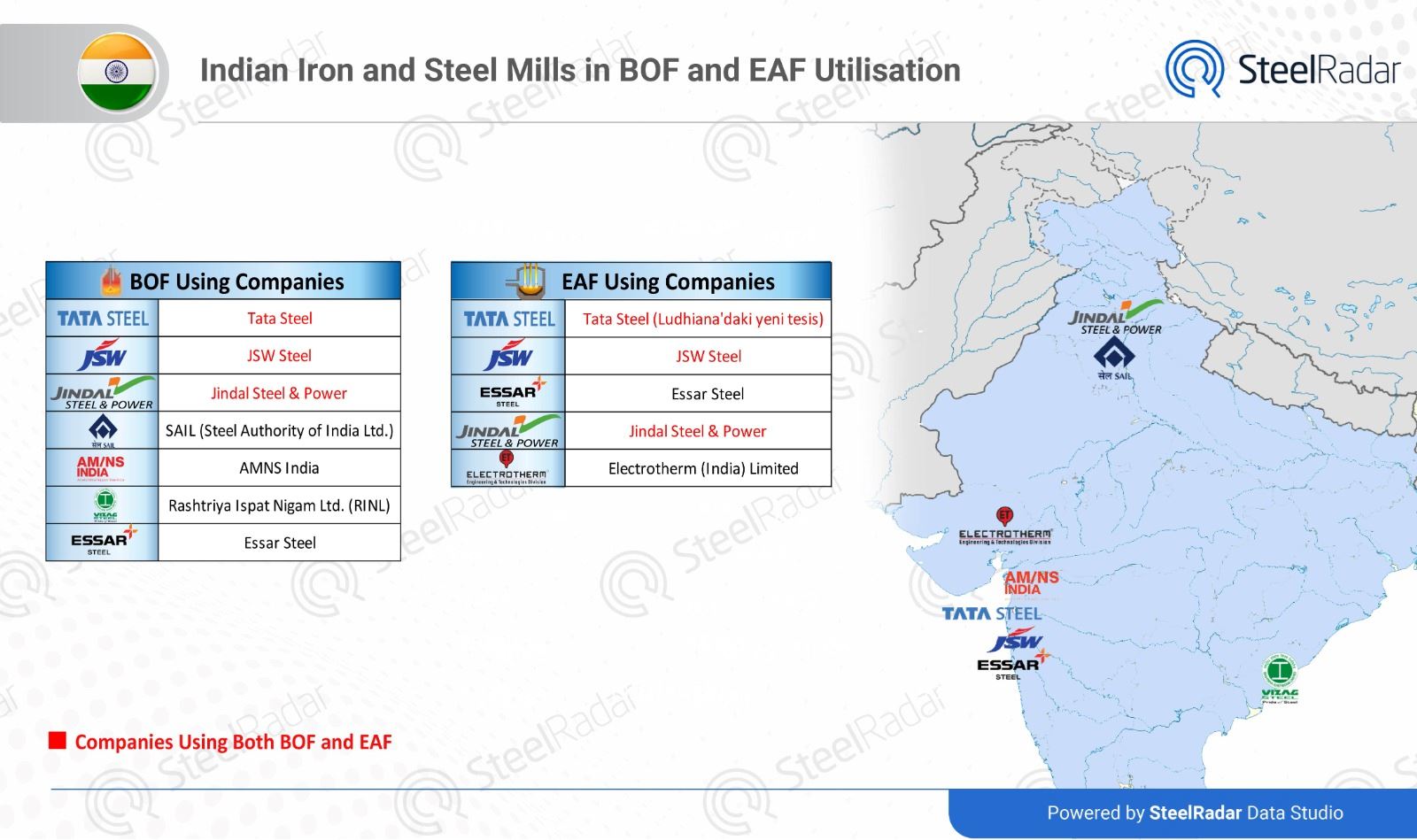

Steel production in India utilizes both basic oxygen furnace (BOF) and electric arc furnace (EAF) technologies. In 2023, 56.4% of the country’s total steel production of 140.8 million tons was generated through the EAF route, highlighting its widespread adoption. However, the BOF route remains significant, especially for large-scale producers.

Among India's leading steel manufacturers are Tata Steel, JSW Steel, Essar Steel, and Steel Authority of India Limited (SAIL). While these companies employ both BOF and EAF technologies, SAIL primarily relies on blast furnace-based production. Tata Steel, aiming to expand its steel production capacity, plans to establish a new EAF facility in Ludhiana with an annual capacity of 750,000 tons. Additionally, the company continues investing in EAF-based processing facilities in southern India.

One of the key producers utilizing EAF technology in India is Electrotherm (India) Limited, a leader in induction furnace and metal refining equipment manufacturing. Meanwhile, Jindal Steel & Power has developed the world’s first coal gasification-based direct reduced iron (DRI) plant at its facility in Angul, Odisha, aiming to reduce dependence on imported coking coal.

Regarding green steel production, India is making significant strides toward its goal of producing five million tons of green hydrogen annually by 2030. Gensol Engineering, in collaboration with the Matrix Gas & Renewables Consortium, is preparing to develop the country’s first green hydrogen-powered steel production plant. Supported by the Ministry of Steel and MECON, this project will utilize direct reduced iron (DRI) vertical shaft technology to significantly reduce carbon emissions.

Under the National Green Hydrogen Mission, the Indian government is offering substantial incentives to promote green steel production, while major industry players continue to increase their investments in sustainable manufacturing.

Comments

No comment yet.