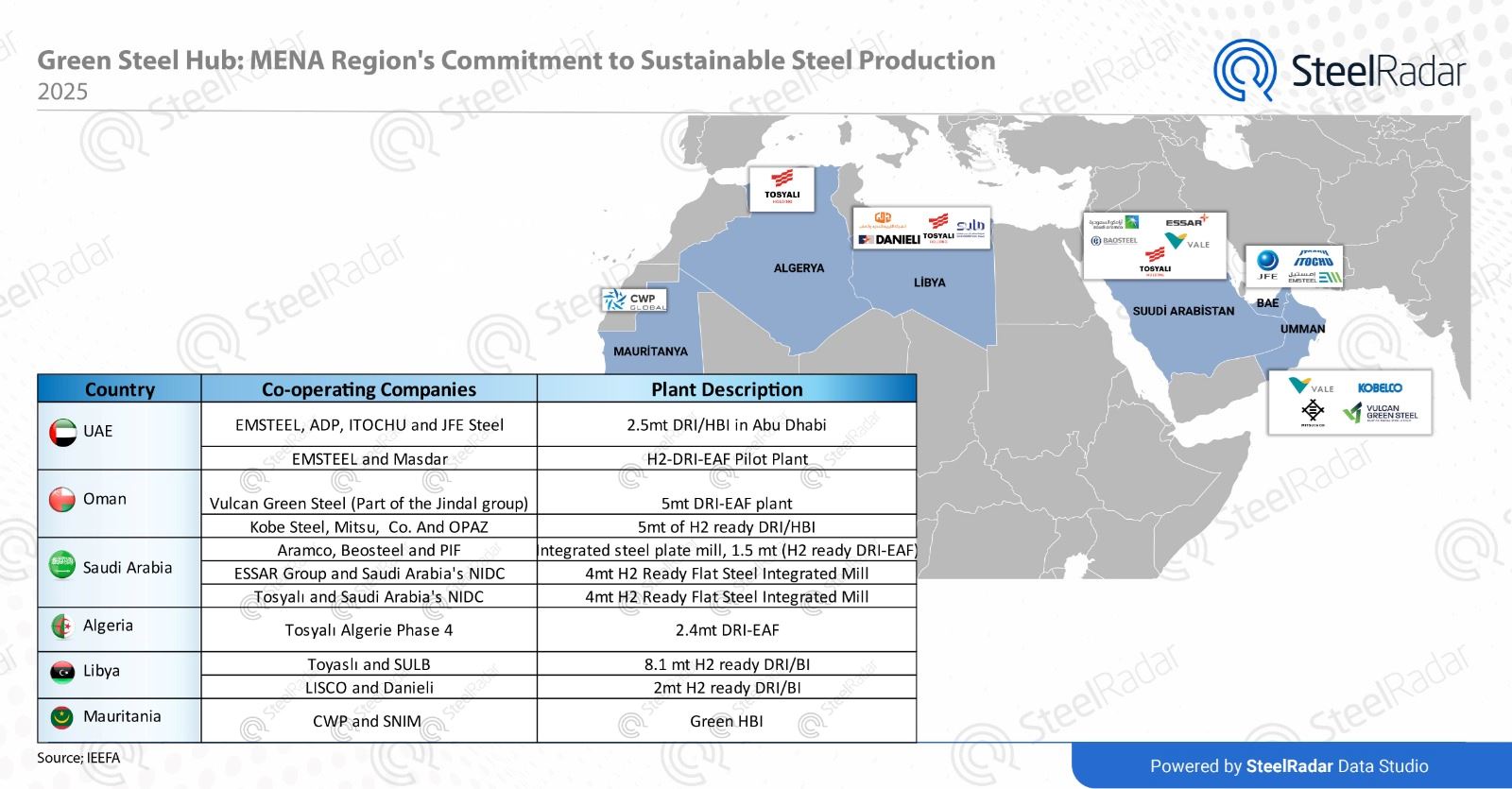

According to the Institute for Energy Economics and Financial Analysis (IEEFA), the MENA region is rapidly emerging as a global leader in sustainable steel production through significant investments in green technologies and renewable energy sources.

The Middle East and North Africa (MENA) region is rapidly transforming into a global leader in sustainable steel production, with numerous countries and companies investing heavily in green steel initiatives. As the world increasingly prioritizes environmental sustainability, the MENA region is at the forefront of this transition, showcasing its commitment to reducing carbon emissions in the steel industry.

In Mauritania, CWP Global is leading the way with the GREEN HBI project. This initiative aims to produce high-quality Hot Briquetted Iron (HBI) using renewable energy sources and significantly reduce the carbon footprint associated with traditional steelmaking processes.

Tosyalı in Algeria is preparing to introduce 2.4 million tons of DRI and EAF technology. This advanced method not only increases efficiency but also minimizes greenhouse gas emissions, positioning Algeria as a key player in sustainable steel production.

Libya is witnessing an increase in green steel projects and many companies are contributing to this cause. The Libyan iron and steel company plans to produce 2 million tons of DRI/HBI together with DANIELI. Tosyali and SULB also have ambitious plans to produce 8.1 million tons of DRI/HBI, aiming to produce 2.5 million tons of DRI in the first phase.

Saudi Arabia is emerging as an important center for green steel production with a large number of companies investing in sustainable technologies. Saudi Arabia is preparing to produce 4 million tons of DRI-EAF with Tosyalı, and with ESSAR Gruop.

Aramco, Baosteel and PIF are collaborating on an integrated steel production facility and a 1.5 million tons H2-DRI-EAF project. ESSAR Group and Saudi Arabia's National Industrial Development Center (NIDC) are building a 4 million ton capacity H2 ready-mixed flat steel plant, while the partnership between Tosyalı and NIDC is building a 4 million ton capacity benzene flat steel plant.

EMSTEEL is establishing a 2.5 million-ton DRI/HBI facility in Abu Dhabi in partnership with ADP, ITOCHU and JFE Steel. EMSTEEL and Masdar are also developing a H2-DRI-EAF pilot plant.

Impact and Future Outlook These investments and initiatives across the MENA region are expected to significantly reduce the carbon footprint of the steel industry, contributing to global efforts to combat climate change. By adopting advanced technologies like DRI-EAF and utilizing renewable energy sources, these projects will not only enhance the region's competitiveness but also promote sustainable development. Looking ahead, the MENA region is poised to play a crucial role in shaping the future of the global steel industry. As more countries and companies commit to sustainable practices, the region is set to become a model for green steel production, paving the way for a more environmentally friendly and economically viable future.

Comments

No comment yet.