Erdemir, which started its operations in 1965 as one of the most important strategic steps in the development planning of Türkiye, which started serious moves in the field of industry in the 1950s, continues its journey of success with confident steps. Erdemir, which started its production adventure with an annual capacity of 400 thousand tons in order to produce the flat steel needed by the Turkish industry, has increased its capacity to 5 million tons of final products in 59 years.

Erdemir, which was established to support the development of industry and development, has rapidly increased its production capacity and product diversity over the years by signing exemplary investment projects in line with Türkiye's increasing needs. In 2006, Erdemir joined OYAK, one of the leading representatives of the Turkish industry, and its investments have gained great momentum since that period. OYAK's financial strength, vision and management experience provided Erdemir with significant advantages in order to increase its competitive power and accelerate its growth.

Employs more than 12 thousand people

Erdemir, Türkiye's first and largest flat steel producer, operates in the fields of flat and long steel production, steel service center services, mining, industrial gas production, engineering and project management as well as energy with its subsidiaries İsdemir, Erdemir Maden, Erdemir Steel Service Center, Erdemir Engineering, Erdemir Romania, Kümaş Magnesite, Erdemir Energy Erdemir Asia Pacific and İsdemir Linde Gas Partnership. Erdemir, one of the largest employers in the Turkish industry, currently employs more than 12 thousand people. Erdemir, which also plays a major role in the development of the Ereğli region, directly employs approximately 5 thousand people in Ereğli alone.

Erdemir serves many sectors such as automotive, white goods, pipe profile, rolling, general manufacturing, electrical-electronics, machinery, energy, heat appliances, shipbuilding, defense, packaging and renewable energy. Providing products at international quality standards to these sectors, Erdemir produces 536 flat steel grades in hot and cold rolled, plate, tin, chrome and galvanized product groups.

The goal is to achieve net zero emissions by 2050

Erdemir and İsdemir, which announced the Net Zero Roadmap, which shapes its green transformation steps, in the first days of 2024, aims to reach net zero emissions in 2050. Erdemir and İsdemir plan to reduce carbon emissions per ton by 25 percent by 2030 and by 40 percent by 2040 compared to 2022, which they set as the base year.

Erdemir and İsdemir will realize a transformation investment of 3.2 billion dollars by the end of 2030 in order to reduce carbon emissions per ton of crude steel produced by at least 25 percent. Within the scope of these investments, the installation of a SPP with an annual electricity generation capacity of 1 million 710 thousand MWh will also be realized. With the investments to be made within the scope of the Net Zero Roadmap, Erdemir and İsdemir's crude steel production capacity will reach 13 million tons by 2030.

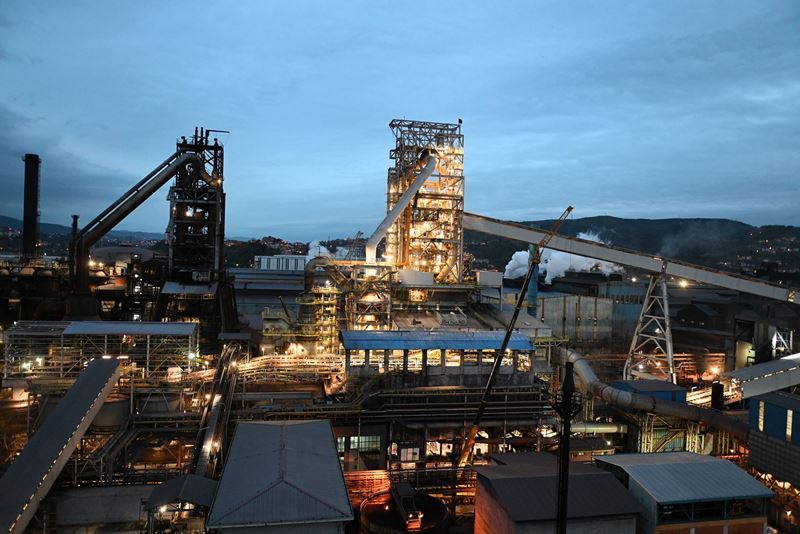

Commissioned its 2nd renovated blast furnace “Zübeyde”

Erdemir renewed its 2nd Blast Furnace “Zübeyde”, named after the mother of Gazi Mustafa Kemal Atatürk, and commissioned it on October 29, 2023, the 100th anniversary of the Republic. Erdemir carried out every stage of the new Blast Furnace, from project design to commissioning, with Erdemir Engineering, one of OYAK Mining Metallurgy Companies. All parameters of the new furnace, which has the latest technology, can be monitored effectively. The 2nd Blast Furnace, whose capacity increased from 1 million 625 thousand tons to 1 million 775 thousand tons, will significantly increase Erdemir's occupational health and safety and environmental performance.

Built to replace the previous blast furnace, which produced 60 million tons of liquid crude iron during its 45-year operation, the new Blast Furnace is expected to serve for 50 years or more.

Comments

No comment yet.