In January, the group announced plans to invest in an electric arc furnace to decarbonize steel production, aiming to meet European Union targets to reduce carbon emissions. However, the project's start date was delayed due to insufficient subsidies and regulatory uncertainty.

According to the new plan, the construction of the electric arc furnace and the completion of other infrastructure investments are targeted two years after 2028. The electric arc furnace offers a production process with a lower carbon footprint by using recycled scrap instead of iron ore. However, this process requires more energy than blast furnace smelting.

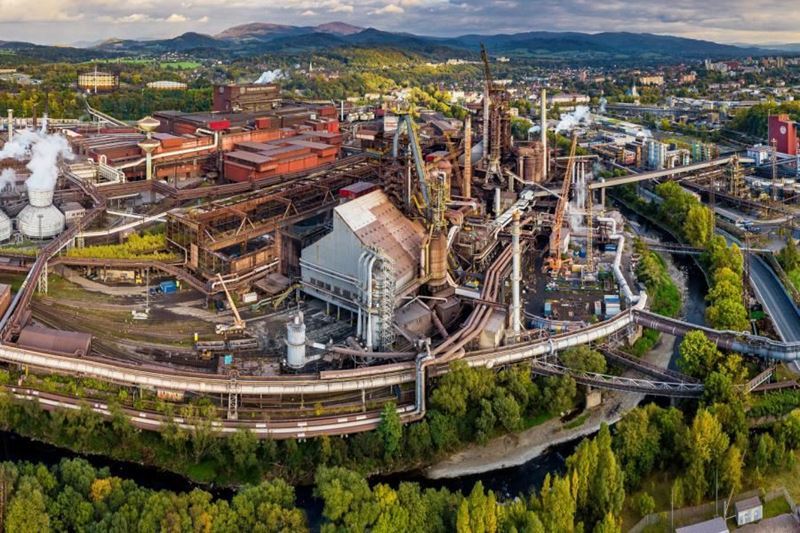

Petr Popelář, Chairman of the Board of Directors of Moravia Steel, stated that the first investments in the project began last fall, while this year the construction of a combined cycle gas turbine (CCGT) at the Třinec Energetiky power plant began, replacing the coal-fired power plant.

Popelář continued: "The traditional production of blast furnace raw material is based on the hot sintering of iron ore. We will replace this with briquette production, i.e. a cold process. This will avoid about 70,000 tons of CO2 emissions per year. That's an emission reduction equivalent to about 19,000 passenger cars,"

Reasons for the project's delay include low subsidies, uncertainty about the future of the European Green Deal and competition from low-cost steel importing countries. The lack of clarity on regulations to protect the European market was highlighted by the group as a major obstacle.

Half of the restructuring costs in the energy sector will be covered by support from the Modernization Fund. The group will continue negotiations with the government and the European Union to realize the project.

Moravia Steel emphasized that the decarbonization project is not an investment to increase the commercial value of the company, but a mandatory regulatory requirement. The cost of the project is expected to reach tens of billions of crowns.

Comments

No comment yet.