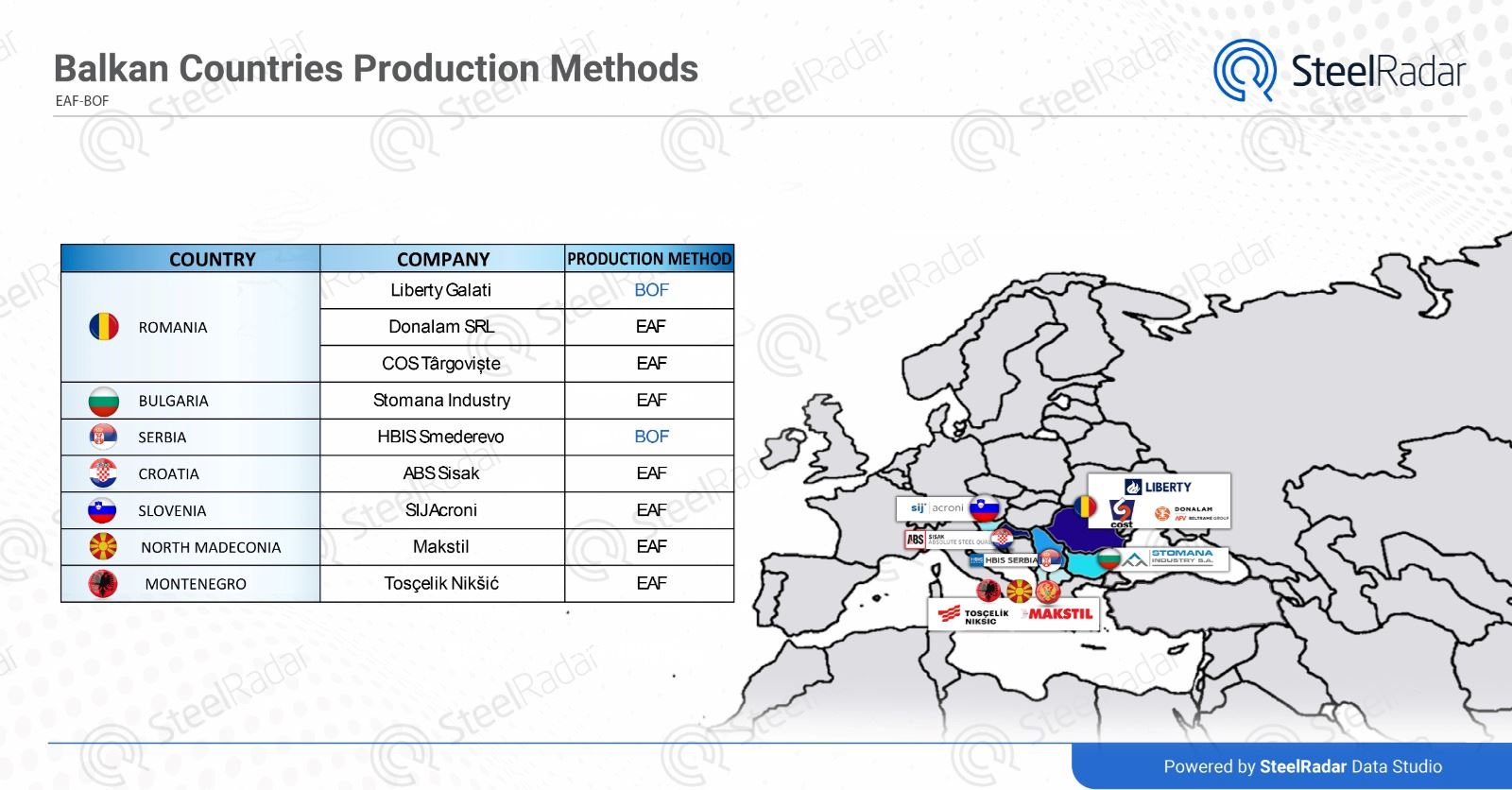

Technological differences in steel production in the Balkans

Steel production in the Balkans shows technological differences. Electric Arc Furnace (EAF) technology is favored by many producers due to its environmentally friendly processes and flexible production capacity. However, Basic Oxygen Furnace (BOF) technology is commonly used in large production facilities.

In Romania, EAF (Electric Arc Furnace) technology is common in local plants, while large integrated plants like Liberty Galati use BOF (Basic Oxygen Furnace) technology. These large plants in Romania continue to invest in line with their eco-friendly production goals. For example, Liberty Galati announced plans to invest up to 1 billion Euro by 2030 with the goal of becoming carbon neutral. This transformation aims to reduce CO₂ emissions by 80% by improving energy efficiency and advancing Romania's position in eco-friendly steel production. The company offers a wide range of products, including hot-rolled products, galvanized products, cold-rolled products, and organic coated products.

AFV Beltrame Group, plans to modernize the COS Târgoviște facility in Romania, which it acquired for 33.3 million Euro, with investments aimed at achieving eco-friendly production goals. The group is also continuing to increase production capacity and support environmental sustainability with its Donalam plant. AFV Beltrame Group’s product portfolio includes IPE and IPN profiles, special steels, rebar, and other products.

Major producers like HBIS Group in Serbia are also investing in eco-friendly production processes, aiming to reduce their environmental impact through the production of low-carbon steel products and energy efficiency projects. HBIS Group produces hot-rolled and cold-rolled steels.

Stomana Industry, located in Bulgaria, is the country's sole large steel producer and uses EAF technology while focusing on sustainable production methods. By offering low-carbon steel products and implementing projects focused on energy efficiency and recycling, the company is taking steps to protect the environment. Its product range includes hot-rolled plates and rebar for the construction, automotive, energy, and mining industries.

Global competition and local sustainability

Steel producers in the Balkans are aiming to stand out in the global competition by adopting sustainable production processes. For example, Tosyalı Holding announced plans to invest 35 million Euro in the Zeljezara AD Nikšić steel plant in Montenegro within the next three years. Tosçelik Nikšić aims to make Montenegro a key center for engineering steels in Europe with this move. While producing high-quality special steel products for the automotive and construction sectors, the company is committed to minimizing its environmental impact. Tosçelik is not only Europe's third-largest pipe producer but also Turkey's largest pipe producer and largest structural steel producer.

Croatian steel producer ABS Sisak has taken significant steps in environmental sustainability and efficient resource use with EAF technology. The company promotes recycling in its production processes and uses advanced technologies to ensure energy efficiency. Its product range includes long products for the construction, automotive, and engineering sectors.

SIJ Acroni, based in Slovenia, focuses on resource efficiency, waste reduction, and reducing carbon emissions while prioritizing recycling and circular economy practices. The company aims to operate with the most environmentally sensitive principles by producing high-quality steel products using EAF technology. It provides steel solutions for industries such as aerospace, automotive, chemicals, construction, energy, heavy machinery, and oil and gas.

Makstil is a company based in North Macedonia, primarily focused on the production of hot-rolled steel plates. It combines its corporate social responsibility approach with environmentally conscious production, contributions to the local community, and sustainability development goals.

Comments

No comment yet.