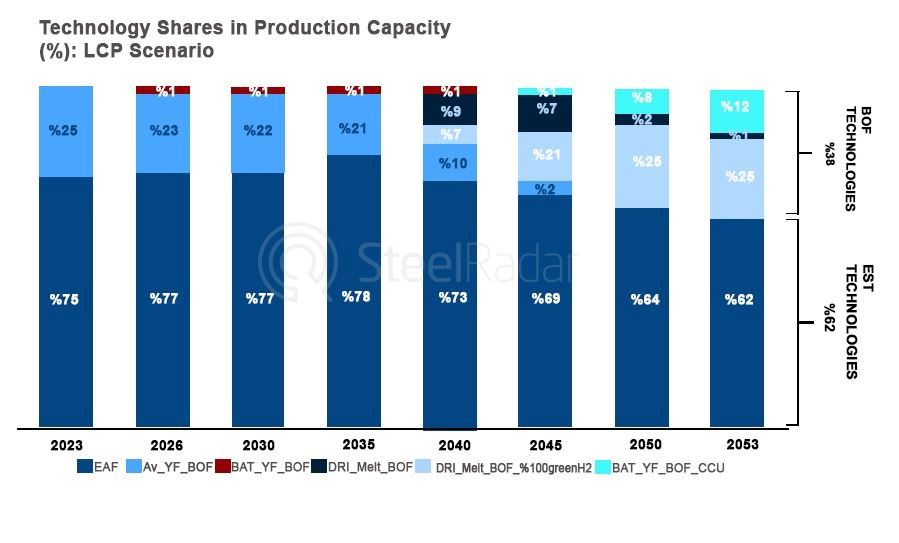

According to this roadmap, significant changes are foreseen in the technologies used in steel production. According to the optimal scenario, the distribution of technologies used in steel production until 2053 is as follows:

- Electric arc furnace (EAF): 62

- Hydrogen-based (DRI) and DRI-Melt-BOF: 25%

- Green hydrogen: 100%

- Blast furnace and carbon dioxide capture, storage and utilization (BOF CCUS): %12

The steel industry is aiming to significantly reduce carbon emissions in order to achieve these targets. The optimal scenario envisages a 20.6% reduction in emissions by 2040 and a 99.7% reduction by 2053.

Technological transitions will lead to significant changes in the industry. Blast furnaces will not be closed, but the transformation process will continue. While the electric arc furnace route will remain important, the transition to Hydrogen Based DRI and hydrogen-based technologies will accelerate.

For achieving the projected targets, the steel industry is planning the integration of various technologies. In this context, while natural gas-based DRI is expected to have an important place, the transformation will accelerate with the combination of hydrogen and CCUS technologies in the coming years.

The 2053 targets call for green hydrogen technologies to reach 25% and CCUS technologies to reach 12%. Thus, a significant carbon reduction will be realized in the sector and environmental sustainability will be ensured.

Türkiye's steel industry is taking decisive steps towards a sustainable future. Investments and technological transformations will make significant contributions to the sector's achievement of its emission reduction targets.

Comments

No comment yet.